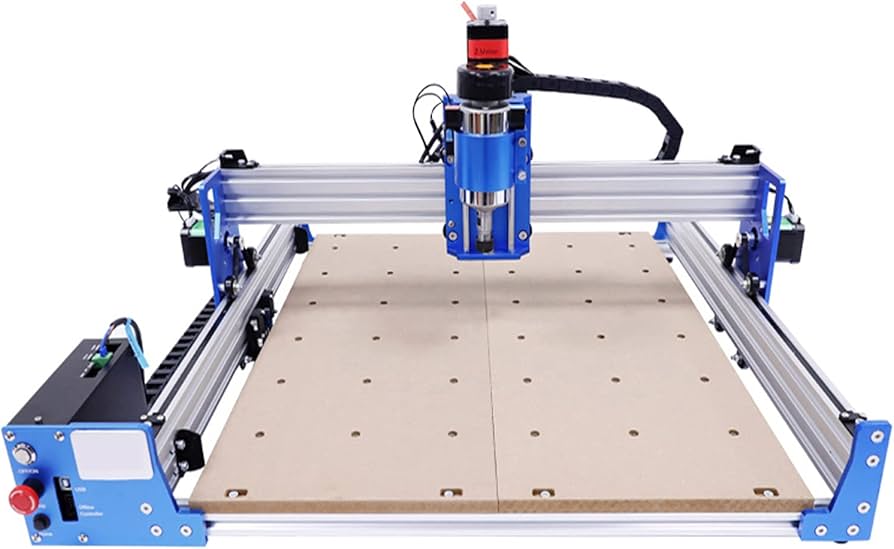

How to Inspect a CNC Machine Before You Buy

Choosing the correct investment in a CNC (Computer Numerical Control) machine is crucial. A CNC machine is a major outlay of money that will affect the effectiveness and success of your operations.

Whether you are purchasing a secondhand or brand-new CNC machine, you really should do an extensive inspection. The basic actions to check a CNC machine before you buy it will be discussed in this article.

Understand Your Needs First

Sort your particular needs before delving into the technical specifics. Are you looking for a CNC machine that can laser cut, mill, or turn? What kind of metal, plastic, or wood are you going to be working with? Knowing your production goals, budget, and space restrictions can enable you to focus your choices and direct the inspection process.

Check the Machine’s Age and Usage

Ask about the age and use history of any secondhand CNC machine you are buying. Though they might need more upkeep, older PCs can nonetheless run well. Find out whether the machine was utilized primarily for occasional projects or in a manufacturing setting. This will help you to understand the possible wear and tear you could run across.

Inspect the Physical Condition

A lot about the history of the CNC machine can be revealed by its physical condition. Search for obvious deterioration, such as cracks, rust, or worn-out parts. Specifically consider the housing, axis, and tool holders of the machine. Should the machine seem to be poorly kept on the surface, inside problems most likely exist as well.

Evaluate the Control Panel

A CNC machine’s control panel is its heart. Verify that switches, knobs, and buttons all operate as they should. See how clear and responsive the display screen is. Turn on the machine and negotiate its software interface if at all possible. Look for latency or error messages; these could point to hardware or software problems.

Assess the Spindle and Axis Movement

Among the most important parts of a CNC machine is the spindle. Look for odd vibrations, sounds, or overheating. See how precisely and smoothly the axis moves. The axes (X, Y, and Z) can be moved by hand to make sure they don’t get stuck or out of place. Any anomaly in these motions could affect your machining accuracy.

Review the Machine’s History and Maintenance Records

Request the repair history and maintenance log for used machines. Regular maintenance suggests the former owner gave the machine good care. Search for specifics about changed components, lubrication plans, and any reoccurring problems. A well-documented past might enable you to forecast required future maintenance.

Run a Test Cut

One of the best tools available for evaluating the performance of a CNC machine is a test cut. Demand to do basic machining work to assess the machine’s general operation, speed, and precision. Look for odd noises during the test and see how the machine runs the operations.

Verify Software Compatibility and Updates

Operating CNC machines depends on software; thus, obsolete or unsuitable software can cause inefficiencies. Verify whether the machine’s software is current and compatible with your design applications. If you are purchasing a used system, find out whether the software license is transferable or whether you will have to acquire a new one.

Consider the Availability of Spare Parts and Support

The greatest CNC machines also need sporadic repairs. Make sure the model you are thinking about has easily available spare parts. Look also at if the manufacturer or merchant provides technical help. Should problems develop, a computer with fewer support choices could end up costing more over time.

Consult with an Expert

If you’re new to CNC machines or unsure about the inspection procedure, think considering bringing along a seasoned specialist. Their knowledge will enable you to see possible red flags and guide your choice.

Make an Informed Investment

Inspecting a cnc machine for sale before making your purchase is a crucial step in protecting your investment. By carefully evaluating the machine’s physical condition, performance, and compatibility with your needs, you can ensure it will serve your operations efficiently and effectively.

Take your time, ask questions, and don’t hesitate to seek expert advice. A well-chosen CNC machine can become a cornerstone of your production process for years to come.