How Protein Powder is Made

“Tell me what you eat, and I will tell you what you are.”

– Jean Anthelme Brillat-Savarin

You ever wonder what’s really in that scoop of “Muscle Explosion 3000” powder you’re blending into your smoothie? If Brillat-Savarin was right, then most gym bros are part cow, part pea, and maybe a little bit egg.

Let’s break down how your favorite muscle fuel goes from the farm to your shaker bottle.

How Protein Powder is Made

1. Raw Material

First, we need to source our protein.

- Whey and casein: Milk from dairy cows

- Plant proteins: Soybeans, peas, rice, hemp seeds, etc.

- Egg protein: Egg whites

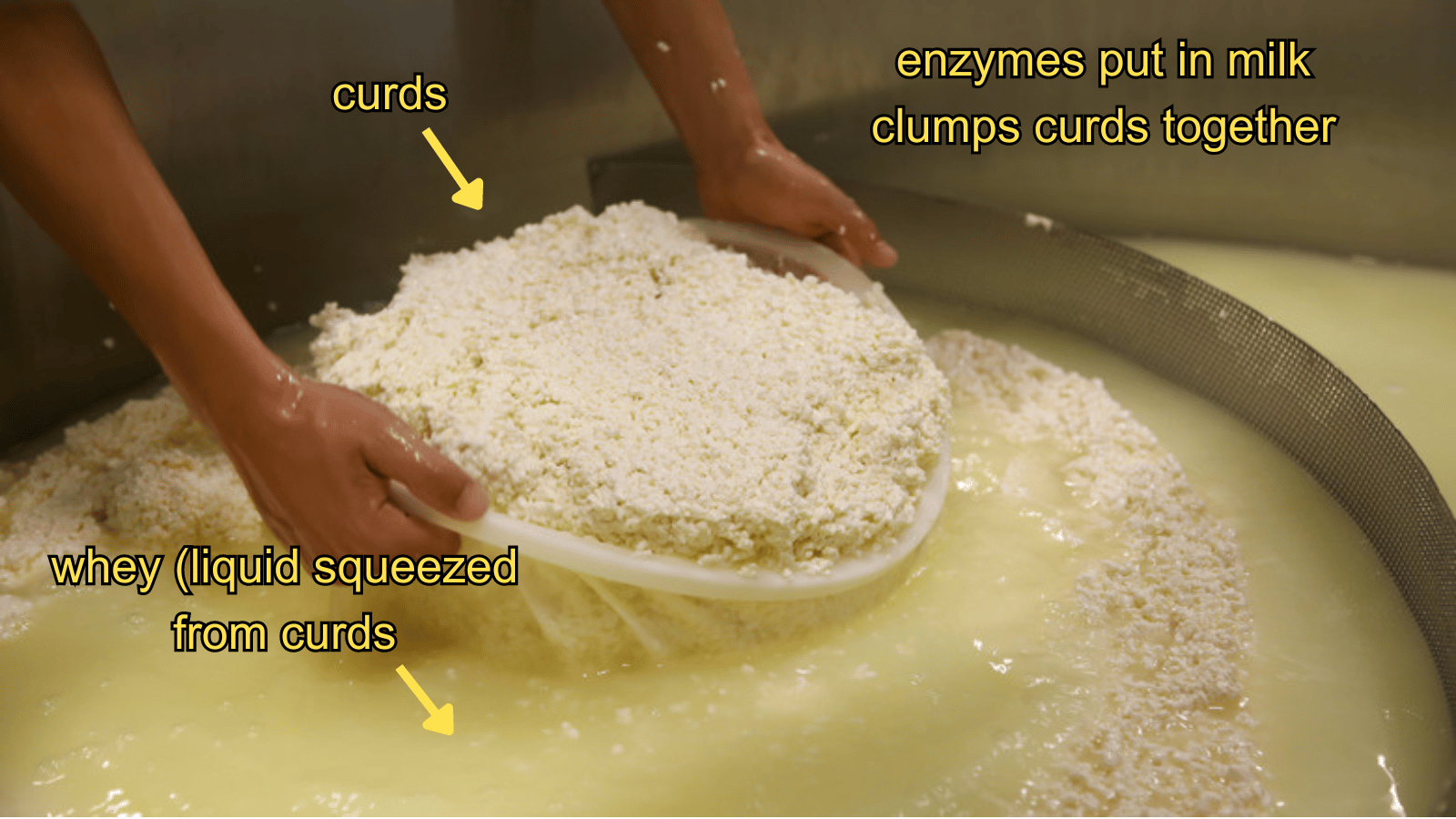

2. Protein Extraction

Next, we need to take the protein out of our raw ingredients.

- Whey: Enzymes are added to milk to separate it into curds and liquid whey (curds are used to make cheese, whey used to be thrown away but now is kept for protein powder)

- Plant proteins: The plant is cleaned, dehulled, and then ground and the protein is separated

- Egg protein: Egg whites are separated from yolks

3. Filtration

This stage is about removing fats, carbs, and as many other non-protein things from the liquid as possible:

- Whey goes through micro-filtration and ultra-filtration

- Plant proteins use membrane filtration or centrifugation

This step creates protein concentrates (60-80% protein) or isolates (90%+ protein)

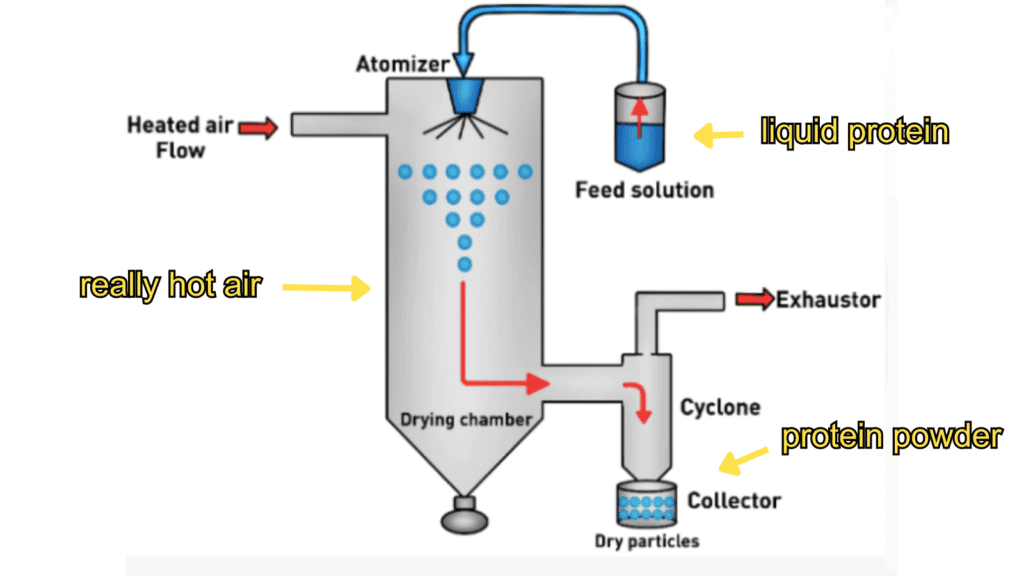

4. Drying

Now we have to turn our liquid protein into powder. How? Spray drying

We spray the wet protein into hot air. The water goes away, and we get powder!

5. Flavors, Testing, and Packaging

Last steps include:

- Adding flavors (vanilla, chocolate, cinnabon, blueberry muffin, you get the idea)

- Make sure its safe. Quality testing for protein content, purity, and safety

- Package it up in bags or tubs

And there you have it! From cow, soybean, or pea to your post-workout shake. It’s a process that’s part science, part food production, and all gains baby.

Stay swole,

Josh